How digital helps deliver CCUS projects at speed and scale for climate action

Carbon capture, utilization and sequestration (CCUS) is crucial to achieving global net zero ambitions. So says the International Energy Agency (IEA) (ref 1)—stating that CCUS can account for nearly 15% of the cumulative reduction in emission. But there’s a problem. The cost of this technology needs to fall sharply to make it viable at scale. Without higher levels of efficiency, safety, and better decision making, the economics of CCUS will not shift. This article is an exploration of how digital technologies can make the difference, turning CCUS into a powerful component of climate action strategy.

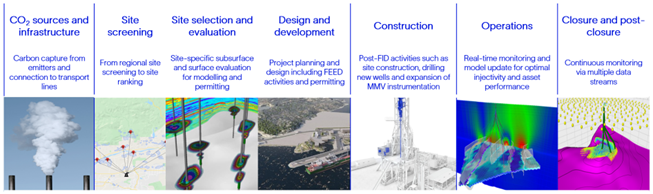

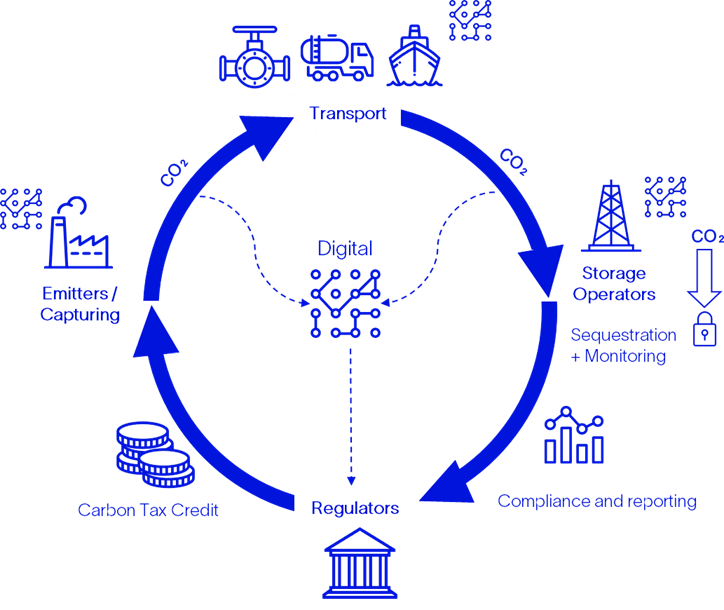

New regulatory frameworks are aiding CCUS economics, and the number of new projects has increased rapidly in recently years. The capture capacity of projects under development and the number of facilities has doubled in the last 12 months (ref 2). However, due to a variety of technical and economic challenges faced throughout the CCUS project life cycle (figure 1), many projects under development are failing to materialize. Innovative digital technologies can provide a paradigm shift to overcome each of these challenges. For example, advanced simulation tools enable faster and more accurate optimization of capital-intensive investments in the planning phase, while AI and automation can improve project performance and conformance, as well as driving down operational costs.

Digital technologies play a big role across the life of a CCUS project

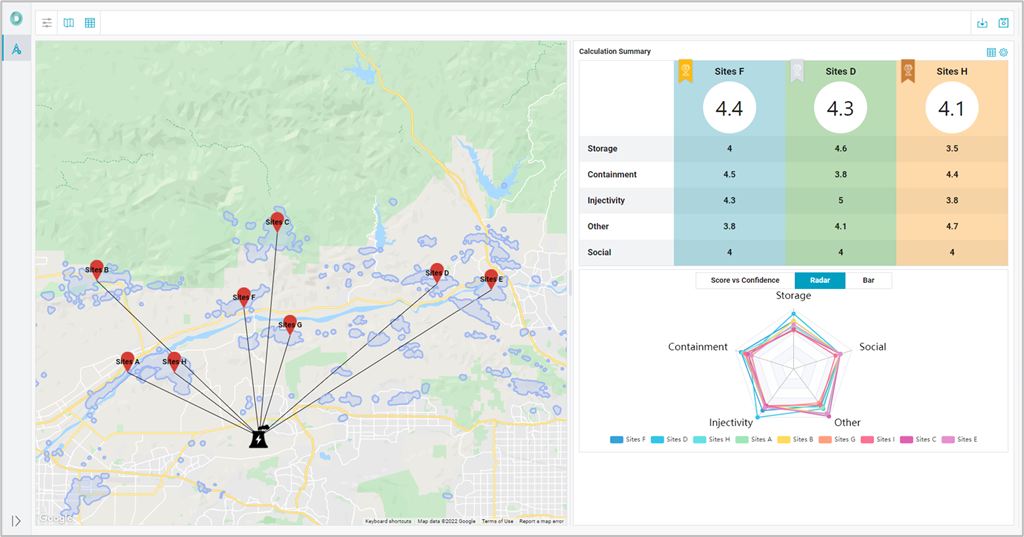

In the early phases of a CCUS project, it is important to screen large areas for the best site(s) by taking into consideration all technical performance factors such as capacity (how much carbon dioxide (CO2) can be stored?), injectivity (how fast can we inject CO2?) and containment (the assurance that CO2 remains confined in the pore space over time).

In addition to the technical factors, there are equally critical non-technical requirements, such as proximity of the emitters and existing transport networks to the storage site, the presence of legacy wells in the area, monitorability (ability to monitor CO2 migration in the subsurface via instruments), legal requirements, public opinion, proximity to sensitive areas, and most importantly the techno-economic evaluation of the project. Such detailed analysis typically takes many years, is often based on a limited amount of data, and involves many decision makers and stakeholders. Quite often, ad-hoc decision making takes place, making the decision process framework non-repeatable and inconsistent.

Start your CO2 storage site screening and ranking project on the best footing with collaborative digital technologies and science

Digital technologies can help accelerate the permitting process by ensuring that a comprehensive and consistent screening methodology is applied systematically to multiple assets across the globe. First, the stakeholders need to discuss and agree upon the criteria that will be used to rank the sites and ultimately select the best one(s).

A collaborative digital space in which all data is shared with all technical and non-technical stakeholders and decision makers, with the appropriate entitlement and access control tools makes this process reliable, unbiased, data-centric, and traceable.

The various criteria are not always quantitative, and they conflict with each other as they try to address different risks. Their relative importance generally depends on the context. At SLB, an analytic hierarchy process (AHP) is used to determine the relative weights of different decision criteria. AHP has the ability for quantitative and qualitative evaluation of attributes, enabling simple and effective determination of relative weights by comparing attributes in pairs. Next, the intuitive Technique for Order of Preference by Similarity to Ideal Solution (TOPSIS) is applied to calculate site scores and rank sites by comparing each weighted criterion simultaneously for all sites. Monte Carlo simulation is used for uncertainty analysis considering the uncertainty of site properties, and a sensitivity analysis is provided to show how the ranking results change when inputs vary.

This digital framework enables a vast amount of data to be harnessed, from public sources (world maps, public repositories, multi-client seismic data, well data, etc.) as well as proprietary data (2D/3D seismic, well logs, etc.). The scalability of the digital approach makes the site ranking and selection process more accurate and efficient, allowing us to consider a vast number of scenarios and simulate their likelihood, explore uncertainty in greater detail than humans would otherwise be able to do, and ultimately enable more informed decision making.

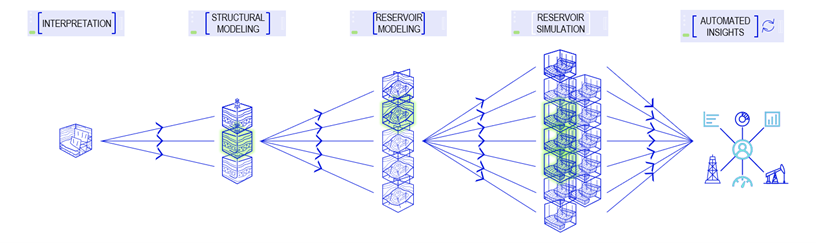

Accelerating the planning phase

Once a storage site has been selected, the detailed evaluation and characterization process begins. CCUS projects tend to have many unknowns and parameters, which makes the use of deterministic approaches unsuitable. However, it is nearly impossible to consider all parameters using a manual approach due to the large number of variables that can affect the quality of the storage site (porosity, permeability). This is why we find that using an automated approach, which generates multiple realizations from structural modeling to reservoir simulation, can dramatically accelerate the characterization phase and enable a better understanding and management of uncertainties. By leveraging AI and cloud scalability, users can gain valuable insights into the potential performance of the project, as well as the key risks. This method is called agile reservoir modeling (ARM) and has been used successfully by customers, such as Northern Lights, to accelerate planning for their first-of-its-kind open-source CO2 storage hub offshore Norway.

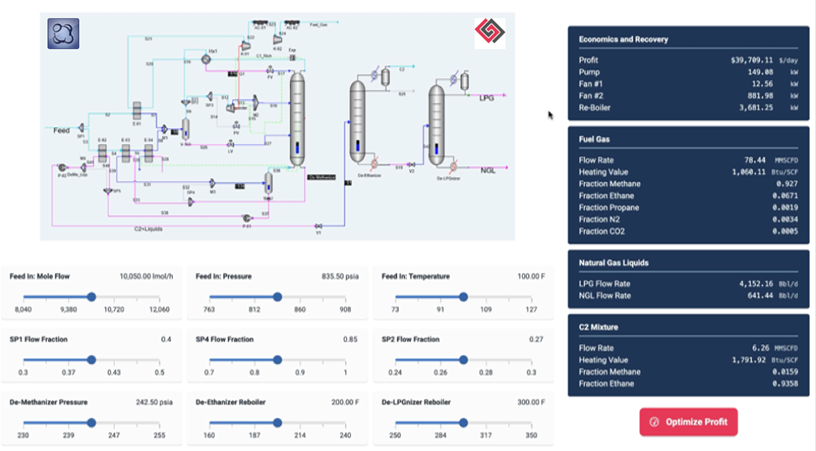

Reducing costs with digital twin technologies

The economics of CCUS projects depend heavily on the cost of carbon capture and transport, which can be up to 80% of the total cost of the project. These costs also make up the majority of operational and maintenance costs. Failing to optimize these costs can make an otherwise economical CCUS project uneconomical. The digitalization of surface facilities and transport lines has been advancing in the energy sector, opening the door for enhanced workflows that can help control the costs, reduce risks, and enhance asset performance and reliability. Increasingly, advanced digital twins are becoming more and more prevalent and can provide insights on the behavior of a particular asset (equipment, facility, system). Most digital twins are based on data-centric approaches that provide high-frequency information about the health or performance of an asset. The benefits of this approach are generally limited to conventional maintenance applications, such as condition-based modeling (CBM) and prognostic and health management (PHM). By comparison, rigorous physics-based models can provide critical insights to the performance of the assets, but are generally inadequate for real-time operations because of their relatively slow performance.

Recent developments in AI combining data-centric and model-centric approaches provide a powerful and elegant solution to this issue. These ‘hybrid-AI’ models can run an order of magnitude faster than either data-centric or model-centric approaches. This flexibility and scalability make it possible to run large scale optimization in a fraction of a second and improve the asset health and productivity (Figure 4). This hybrid AI approach was applied to an amine-based carbon capture plant, where it was possible to build a surrogate model that reproduced the same results as a rigorous process-based model (within 1% error), but 100 times faster.

A similar approach was applied to model CO2 transport via pipeline to help prevent common flow assurance issues such as pipeline leak, corrosion, and solid formation. These surrogate models were all built using the ONNX open format and Python recipes, making it possible to combine them in new ways. This open-source approach to model building is opening the door to large scale optimization that can immensely benefit CCUS operations. Imagine the optimization of the entire integrated asset model, from the emitters to the storage site and including the pipeline or ship transportation network, all in a fraction of the compute time.

Breaking silos with digitally enabled workflows and collaborative solutions

Many CCUS operators have raised the point that they are suffering from inefficient workflows inherited from oil and gas practices, where there is also an abundance of untapped expertise, knowledge, data, and resources that can be applied to CCUS projects. In many ways, CCUS projects are more complex than oil and gas projects due to the large number and variety of stakeholders involved (pore space owners, emitters, partners, investors, regulatory bodies, governments, etc.), and to the low maturity of standards or best practices associated with the operations. For CCUS projects to be (or remain) economical, there is a need to achieve more with streamlined teams, leveraging existing expertise and data, and have a holistic approach to the project from its inception phase to its operations and even post-closure. This can only succeed by leveraging digital technologies to extract insights from small amounts of data and use automation and machine learning to enable informed and prompt decision making (figure 5).

Collaboration is critical to ensure CCUS projects can scale at the required pace to deliver meaningful climate action, and more broadly, the success of the energy transition. Collaboration within organizations, between and with suppliers, service providers, partners and regulatory bodies can bring traceability and transparency to the decision-making process. The role of digital technologies goes beyond just connecting data and workflows across capture, transport, and storage of CO2. It extends to a mindset change, by breaking disciplinary and organizational silos through the promotion of data sharing and open collaboration, bringing people together to make the best possible decisions.

Deploying digital at scale impacts the viability of CCUS across the board. As we have seen, the open collaboration that is vital to CCUS is only possible with an interoperable digital platform to connect workflows. And the benefit is greater than improvements in communications: costs are significantly reduced, safety is improved, efficiency increases, and better decision making is enabled. The drive towards net zero carbon emissions by 2050 cannot happen without CCUS—digital technologies shift the economics to make CCUS happen.

There’s more to come… look out for future articles in this series on climate action for industrial sectors.

References and related content:

- CCUS in the transition to net-zero emissions

- Regional overviews – Global CCUS Institute

- IEA CCUS Handbook – CO2 storage resources and development

- SLB site screening and ranking

- Agile reservoir modeling

- Northern Lights presentation on Agile Reservoir Modeling - SLB Digital Forum 2022