Product overview

The Pipesim™ steady-state multiphase flow simulator is the flagship SLB well and network modeling software for steady-state multiphase flow simulation. Together with the Olga™ dynamic multiphase flow simulator, SLB provides a complete software solution for design and optimization of production systems.

These notes accompany the release of Pipesim 2025.1. The notes describe changes in Pipesim 2025.1 relative to Pipesim 2024.3. This document should be read by all users of the program. The complete program documentation consists of Pipesim help, release notes, and installation guides.

The SLB Software Support Hub provides useful information about the product, and a knowledge base. Please contact SLB if problems or missing functionality are encountered when using Pipesim steady-state multiphase flow simulator or any of its related software tools.

Release updates

Enhancements in Pipesim 2025.1

- Production and gas lift injection networks combined in the same model

- Multi-point calibration of black oil fluid

- Pipeline integrity: maximum allowable operating pressure

- TUFFP model upgraded to version 2024

- Cloud-based model management

- PythonToolkit improvements

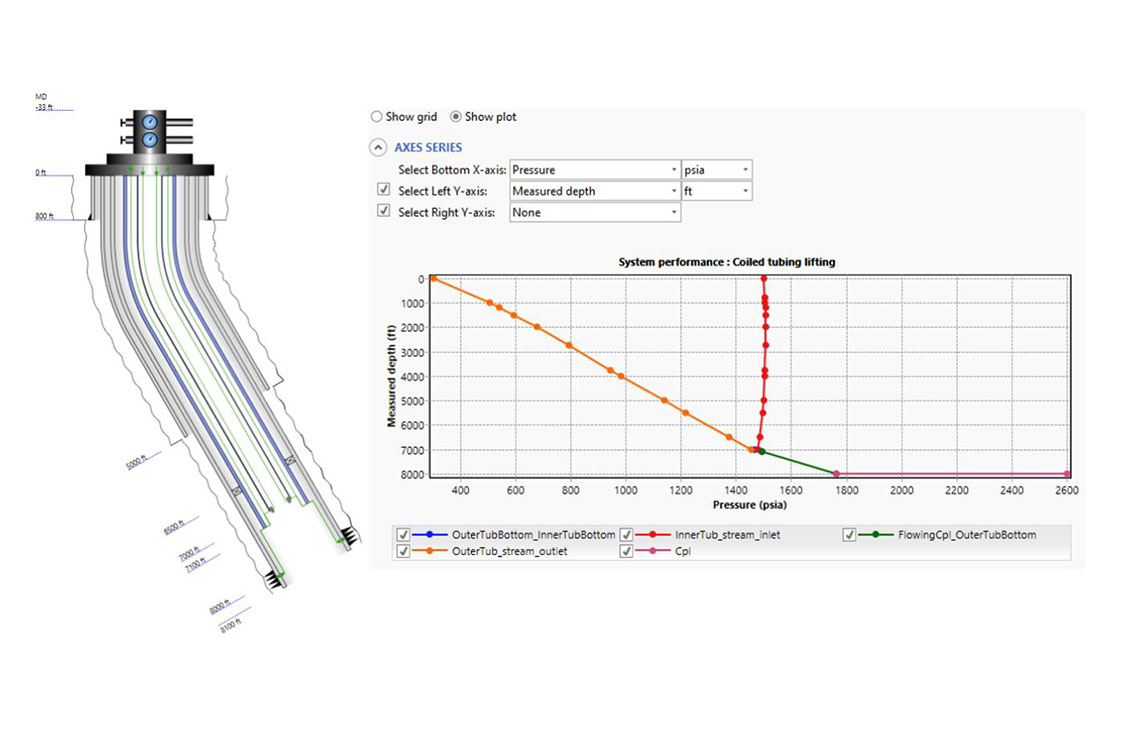

Production and gas lift injection networks combined in one model

The advanced well type was introduced in Pipesim 2023.1 to support complex well scenarios, in which multiple commingled flow paths flow in the same well. During subsequent versions: Pipesim 2024.1, Pipesim 2024.2 and Pipesim 2024.3, the advanced well functionality was further extended to support various well configurations, such as dual strings and concentric tubings. Before Pipesim 2025.1, the advanced well type had only been exposed under the well perspective, and modeling multiple advanced wells in the network perspective was not possible. In Pipesim 2025.1, this limitation is removed. This removal facilitates, among other scenarios, combining production pipeline networks of gas-lifted wells with the gas lift injection flow line network in the same model. This combination is possible because the advanced well facilitates multiple flow ports in the surface, one for the tubing head production, and another for the casing head injection. With this functionality, you can evaluate the impact of gas compression power on the gas lift flow rate distribution and its impact on individual well production.

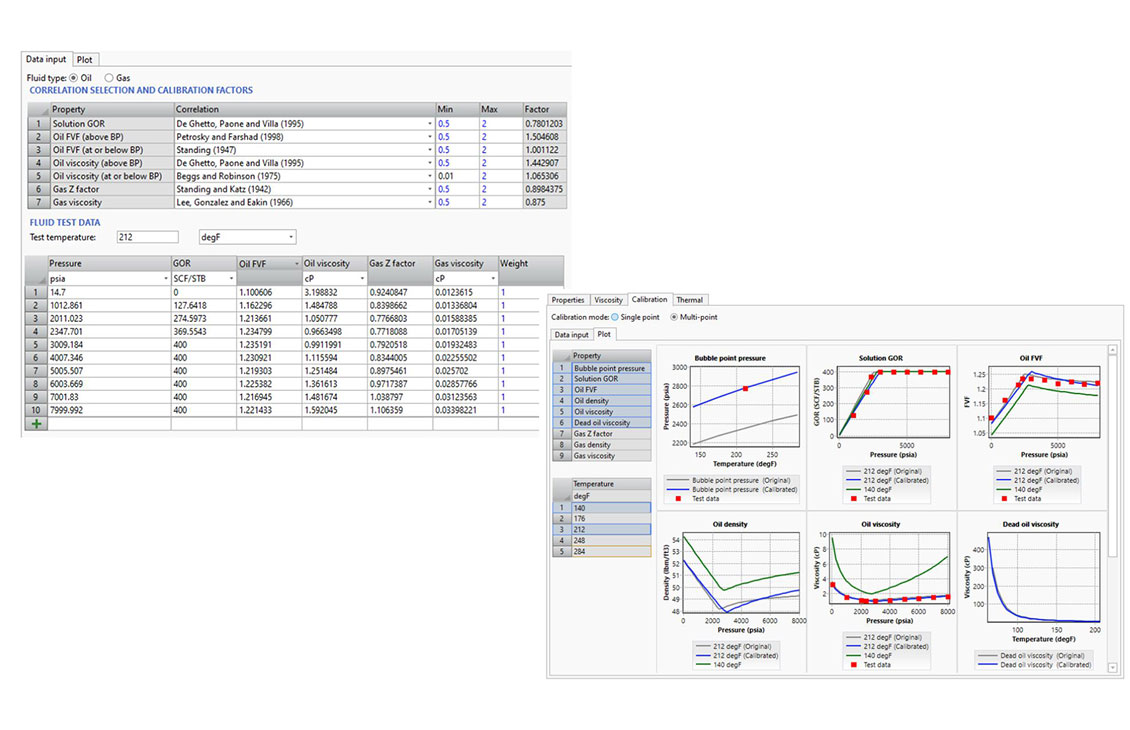

Multi-point calibration of black oil fluid

In previous Pipesim simulator releases, the black oil fluid calibration was limited to a single point, at or above bubble point, with no means for checking the quality and accuracy of the selected correlation in predicting the measured fluid properties. In Pipesim 2025.1, the black oil calibration has a new workflow that facilitates the calibration of the fluid by using a table of measured fluid properties: gas oil ratio, viscosity, formation volume factor (or density), gas compressibility factor (Z) or gas viscosity. against various pressure values at a given temperature. You can select a different correlation for each fluid property and view the tuning factor that is used to adjust the original correlation to match the measured fluid properties. A new ‘Plot’ tab has been added to view plots of all fluid properties to visually quality check the selected PVT correlation plot against the sample fluid properties.

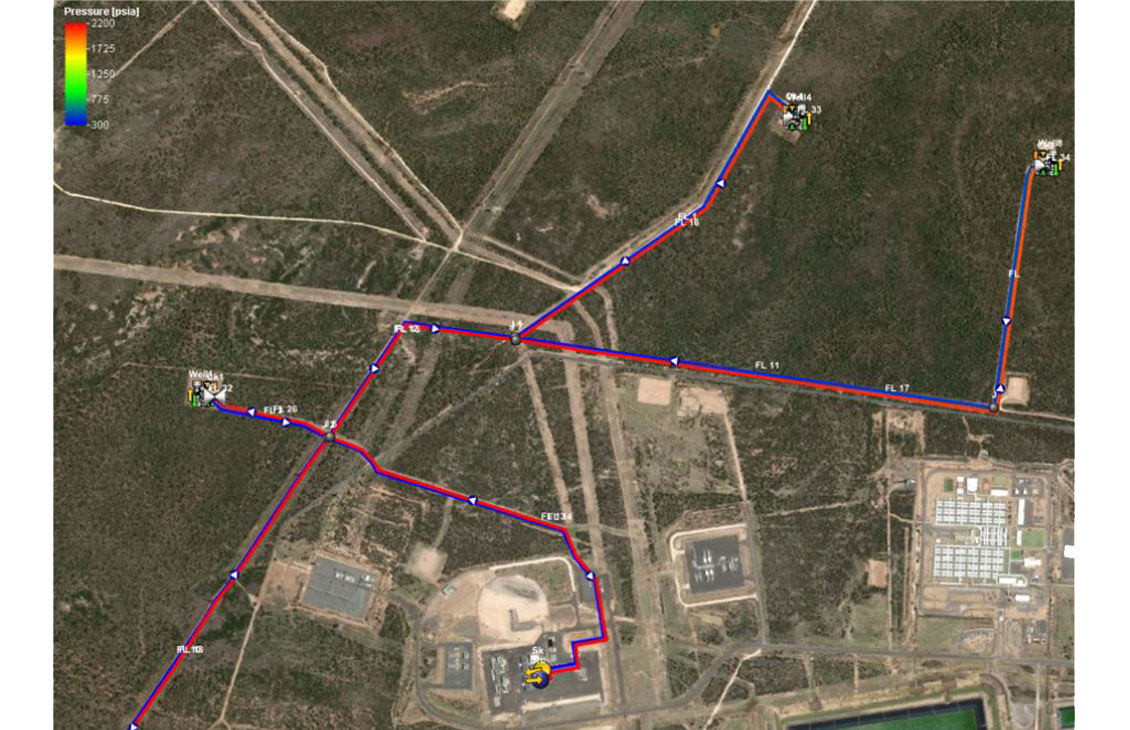

Pipeline integrity: maximum allowable operating pressure

In previous releases, Pipesim simulator could only model and predict two pipeline integrity issues: erosion and corrosion; both are controlled in the simulation settings. In Pipesim 2025.1, a new functionality has been added to predict another pipeline integrity issue, which is the maximum allowable operating pressure (MAOP). The three pipeline integrity issues are now combined under the new ‘Pipeline integrity’ tab in the simulation settings.

The MAOP functionality associates ranges of MAOP ratios with risk factors, to help you easily identify potential problems. You can define customized threshold values, and the risk can be visualized on the GIS map. On the MAOP tab under the Pipeline integrity tab, you can define the thresholds under the MAOP ratio risk index upper limit. If not defined, Pipesim 2025.1 uses default values.

The ratio between MAOP and the fluid pressure is based on a calculated MAOP value or a user-specified one and can be specified locally for individual pipelines.

TUFFP model upgraded to version 2024

Among the various flow correlation and mechanistic models, Pipesim simulator offers access to the TUFFP Unified Mechanistic Model, which is the collective result of many research projects performed by the Tulsa University Fluid Flow Projects (TUFFP) research consortium. The model determines flow pattern transitions, pressure gradient, liquid holdup, and slug characteristics. The model is valid for all inclination angles, pipe diameters, and fluid properties.

Pipesim 2025.1 offers access to the 2024 version of the TUFFP point model, which represents a significant update over the 2011.1 version, with improved performance, robustness, and accuracy. The three-phase model contains separate momentum balances for the gas, oil, and water phases. The model determines whether the oil and water phases are separated or fully mixed. If the phases are separated, individual phase viscosities are used. If the phases are fully mixed, the liquid viscosity is based on the method defined with the Pipesim simulator fluid model, which is useful when rheology data are available. In the latter case, for black oil fluid models, selecting the Brinkman emulsion viscosity method with the Brauner-Ullman water cut off method replicates the TUFFP default method.

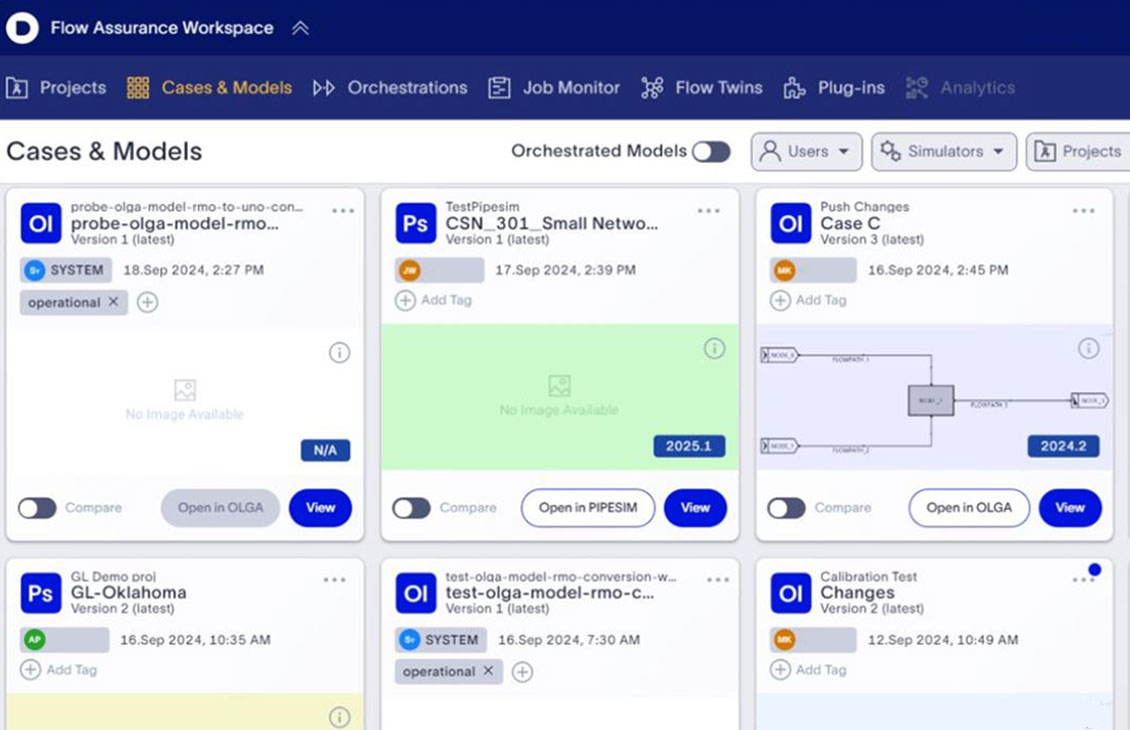

Cloud-based model management

To leverage the accessibility, scalability, and collaboration afforded by cloud computing, the Pipesim simulator, along with the Olga™ dynamic multiphase flow simulator, have been included as subscription-based applications that can be accessed over the internet on the Delfi digital platform without the need to download them locally into a PC. The Pipesim simulator and Olga simulator models associated with the Delf platform have usually been stored under a user’s dedicated virtual machine (VM) and can be transferred from and to the user’s local drive in the PC.

In 2024, SLB introduced a new cloud-based flow assurance model management where the client can have a dedicated model store to save and view model versions, with full control of model access, and the ability to utilize the cloud engine for running Olga models. In 2025.1, several new buttons are now available in the Pipesim user interface to facilitate logging into the cloud model management, uploading models from the local machine into the cloud, or vice-versa.

PythonToolkit improvements

- Support for running the system performance task for simulating advanced well scenarios

- Support for flow control valve simulation results

- PythonToolkit MS Excel case study added for flow control valve sensitivities

- Support for selecting TUFFP 2024 correlation

- Support for MAOP results

- Python environment upgraded to 3.1.2.3