ProdOps Solution Fuels a Companywide Integrated Digital-Field Program at Ecopetrol

In 2019, Ecopetrol initiated a far-reaching, multiyear digital transformation program. Integrated field operations are key to secure the program’s safety, production operations efficiency and effectiveness, and to enhance production performance. Establishing the strategy involved the enterprise deployment of the cloud-based ProdOps tuned production operations solution. This Schlumberger solution was selected because of the company’s extensive applied experience and capabilities in the integrated operations solutions domain.

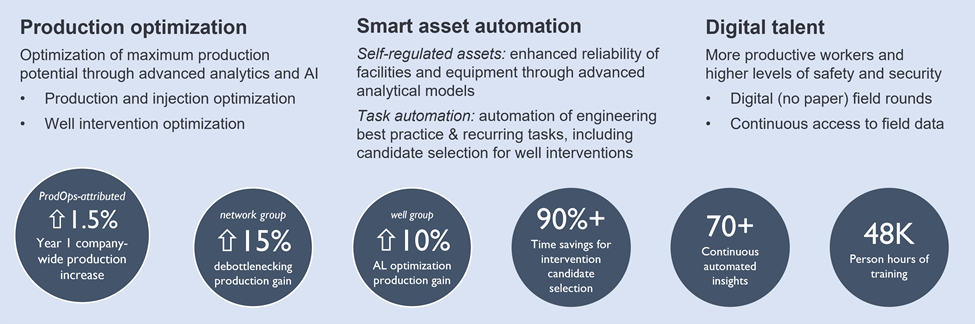

The implementation of the integrated field operations initiative covers 51% of Ecopetrol’s direct production, with 52 fields, 32 facilities, 75 simulated gathering networks and more than 6,500 wells. Leveraging a collaborative partnership and deployment model, the ProdOps solution helped Ecopetrol realize its digital ambitions in well-network surveillance and production optimization workflows.

The solution sets a new industry benchmark in the orchestration and automation of well and network hydraulic diagnostics and production performance at scale.

“The ProdOps solution has helped Ecopetrol to optimize and adjust the production process. It also supports better decisions, making the entire process agile. Now, everyone from operators to middle and top management, can supervise and decide on complete comprehensive views of information from fields, facilities, and networks in a single check”, said Ernesto Gutiérrez de Piñeres, Ecopetrol’s Digital Vice President.

The ProdOps solution enables the optimization of wells based on the simulation of well models and gathering networks. In addition, the solution enables the correlation and analysis of data for monitoring water and fluid quality, monitoring the field factor, monitoring production gaps and the efficiency of the integrated production system. The solution provides the holistic integration of data from well operations, volumetric data from production and injection wells, data from production facilities, mechanical data and historical records of well failures and other events.

The ProdOps solution and other initiatives applied to the integrated fields project, achieved economic benefits at a value of approximately USD 18 million in year 1.

The solution facilitates production management for more than 120 production, reservoir, and chemical engineers, with autocalibrated models and automated advisory insights. This digital solution used an agile development methodology, improved with incremental and nondisruptive software updates.

“The ProdOps solution has enabled Ecopetrol to realize the benefits of speed and decision making quality from automation.” said Patricio Whitney, VP Digital & Integration for Americas Land , Schlumberger. “Ecopetrol now has the foundation and flexibility to fully harness the power of digital on the journey toward the intelligent autonomous oilfield.”

Underpinned by the data integration and access capabilities of DELFI Production Data Foundation, operations and production data is unified from multiple sources, including Sensia’s Avocet and OFM solutions, Rockwell Platform Systems, OSIsoft PI, and others. Surveillance and optimization analysis workflows and visualization dashboards were provided by TIBCO’s Spotfire platform, integrated within the ProdOps solution.

The solution and results achieved by the program to date, establish Ecopetrol as an accomplished ‘fast follower’ for digital implementations. The collaboration provides ongoing support to expand and accelerate the rollout of the ProdOps solution to scale across the Ecopetrol enterprise of wells, fields, and facilities. Enabled by DELFI Production Data Foundation, the delivery of AI solutions and the continuous release of value at scale is now an achievable reality.